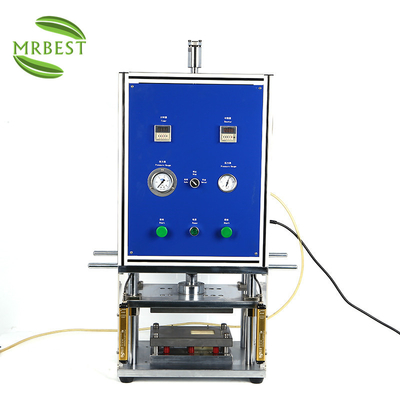

1. Guide pillar structure makes smooth move and high accuracy.

2. It is easy and quick to replace die and regulate the punching depth.

3. Accurate design of die makes no crow’s -feet and corner collapse.

4. Light curtain and cover protection make safety use.

5. The die material is imported from Japan and made of high-strength chrome steel and aluminum alloy with surface treated by

environmental electroplating and painting.

6. Nice appearance, metal plate use solid geometry design which is well formed.

7. Easy operation, small volume, safe and reliable.

2. It is easy and quick to replace die and regulate the punching depth.

3. Accurate design of die makes no crow’s -feet and corner collapse.

4. Light curtain and cover protection make safety use.

5. The die material is imported from Japan and made of high-strength chrome steel and aluminum alloy with surface treated by

environmental electroplating and painting.

6. Nice appearance, metal plate use solid geometry design which is well formed.

7. Easy operation, small volume, safe and reliable.